Education

6 Reasons Why You Should Choose CNC Machining As A Customer – CNC LATHING

Published

3 years agoon

By

techonpc

Why You Should Choose CNC Machining As A Customer – CNC LATHING

What are the 6 main factors that make CNC Lathing so great and very useful from the perspective of the customer?

1: Quick Start

For very low quantities, it is very common that we CNC machine parts from solid rectangular or round billets. Most of these materials are available off the shelf within hours or days of an order being received. It usually takes hours or a few days to program apart on the CADCAM computer. So, by the time we’ve planned, prepped the tools, programmed, and verified the cutter paths, the material has arrived, and away we go. So, it’s a fairly quick start.

2: Minimal Fixturing

Most billets can go straight into a vice, on a mill, or a chuck, on a lathe, and again, away we go. We can even use soft jaws on vices and chunks to grip very complex shapes that are made during the first operation so that we can turn the part over and hold the part for the second operation. Again, this only takes a few hours, so it’s pretty quick to get underway. Very few parts need specialized fixturing, unless you want to do larger quantity production and put dozens of parts on a machine at the same time.

3: Thick Sections

The metal 3D Printing is awesome. But the time it takes to make a part is somewhat proportional to the volume of material in the part. The heavier the part, the longer it takes. With CNC machining, it is almost the opposite. The less material you want to take off, the lower the cost. So, although we can make parts where up to 95% of the material is removed, and we can have very thin sections, as a general rule, CNC machining is great for leaving the material where it is. So, thick chunky designs are no problem.

4: Change Your Mind On a Dime

Another fantastic thing about CNC machining, and for that matter, 3D printing, is that you can change your design any time you like. We can stop and make changes to the CAD-CAM program quite quickly and be back in production in a matter of a few minutes or hours. That’s not so easy with die casting tools, or investment casting, or plastic injection mold tools, added Cut My Plastic.

5: High Precision

CNC machining has got faster and faster over the years. Cycle times have collapsed compared to the past. But they’ve also become more and more precise. 5 microns is now very achievable with CNC Milling when 30 years ago that was only in the realms of grinding. Many companies now do hard milling and hard turning and hold the most breath-taking tolerances. Machines are so precise now, that many have to be kept in 20C temperature-controlled rooms, and the slides have thermal compensation and secondary glass scales for high precision feedback.

6: 5-Axis Wizardry & Verification

The most amazing thing about CNC machining today is the degree to which 5-Axis Machining has developed. The tool and the tool-holder could machine through one side of the net to the inside of the net. This can only be done by using 5-axis CNC machining, but more than that, you have to have the most amazing CAM system, the most amazing verification software, to ensure that you do not crash into the part of the machine.

CNC prototyping machining prices are generally higher and depends on the quality of the machine and its parts. For renting, their prices generally range from $35 – $40 per hour for 3-axis machines, and multi-axis machines cost $75 – $120 per hour.

These major steps forward in what is possible with CNC machining have unchained many designers and allowed them to think way outside the box. In a way, CNC machining has advanced so much in parallel with metal 3D Printing. It is no wonder that we are now starting to see so many amazing hybrid CNC & 3D printing machines. We hope you found that informative, and click HERE to see more!

Follow Me

Unleashing the Power of the Office Accelerator: Maximizing Productivity and Efficiency in the Workplace with Office 365 Accelerator

Unlocking the Hidden Potential of Your Website: Strategies for Growth

From AI to VR: How Cutting-Edge Tech Is Reshaping Personal Injury Law in Chicago

Trending

Microsoft4 years ago

Microsoft4 years agoMicrosoft Office 2016 Torrent With Product Keys (Free Download)

Torrent4 years ago

Torrent4 years agoLes 15 Meilleurs Sites De Téléchargement Direct De Films 2020

Money3 years ago

Money3 years ago25 Ways To Make Money Online

Torrent4 years ago

Torrent4 years agoFL Studio 12 Crack Télécharger la version complète fissurée 2020

Education3 years ago

Education3 years agoSignificado Dos Emojis Usado no WhatsApp

Technology4 years ago

Technology4 years agoAvantages d’acheter FL Studio 12

Technology4 years ago

Technology4 years agoDESKRIPSI DAN MANFAAT KURSUS PELATIHAN COREL DRAW

Education3 years ago

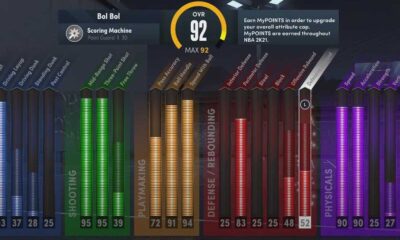

Education3 years agoBest Steph Curry NBA 2K21 Build – How To Make Attribute, Badges and Animation On Steph Curry Build 2K21

You must be logged in to post a comment Login