Education

The Most Common Uses of Injection Molding

Published

3 years agoon

By

techonpcInjection molding is a manufacturing process in which some sort of molten material is injected into a mold, where the material hardens and sets into its new form. This process can be used with all kinds of materials, such as metals, thermoplastics, glasses, and others, and it has been around since the late 1800s.

It was the American inventor, John Wesley Hyatt, with help of his brother, Isaiah, who created and patented the world’s first injection molding machine in the 1870s. Hyatt’s machine was designed almost like an oversized needle, with a plunger that could be depressed to inject plastic through a hot cylinder and into a mold.

Of course, technology has progressed a long way since then, and modern injection molding machines are far in advance of Hyatt’s original creation, but it’s clear to see that this manufacturing method has stood the test of time, being used in countless ways over the years, with new applications still being discovered all the time. Here are some of the most common ways in which the method is used.

Construction

The construction industry is one that has benefited enormously from the power and potential of injection molding technology over the years. Construction companies and professionals can make use of this method to create all kinds of essential parts and products for their day-to-day operations, such as hand tools, fasteners, and other accessories.

There are many advantages to using plastic injection molding for construction, such as the fact that the parts and tools produced tend to be very strong and stable, and the fact that injection molding is often a much cheaper alternative to making tools and parts when compared to other methods and materials like wood.

Medicine

The world of medicine is one that is always developing and evolving, with doctors and researchers always ready to embrace new techniques and technologies in order to further their research and improve their approach to curing diseases and healing patients. For years now, medical professionals have been relying on injection molding to create various tools, implements, and accessories for their day-to-day use.

Plastic injection molding, for example, can be used to make medical-grade parts like surgical tools, X-ray components, testing kits, and so on. Thanks to the power of injection molding, these parts can be made in bulk quantities at incredible rates, helping to meet the needs of today’s hospitals and healthcare facilities.

Food and Drink

The food and drink industry is another one that has made great use of injection molding over the years and has come to rely on this production method in many different ways. When working with food and drink products, it’s vital to ensure that the parts, containers, and tools used to meet the high standards of hygiene demanded by authorities like the FDA, and plastic injection molding can help with this.

This manufacturing method can be used with food-grade plastics that are toxic-free, allowing for such parts to be used in the making and storing of foods and drinks, affordably and effectively, without infringing on any of the various laws and standards for food and drink hygiene. Injection molding can therefore be used for water bottles, food containers, and processing equipment in food preparation facilities.

Automotive

The automotive industry is another significant industry that makes use of injection molding tools and technology on a daily basis for the production of car parts and accessories. When you look at a typical car, for example, you may be able to see many elements that were made with the help of this process.

Various parts of the dashboard, or even the entire dashboard, for example, maybe made via injection molding. Other accessories and features like door handles, window buttons, cup holders, buttons and levers, exterior plastic parts, and so on may all be made with the help of injection molding. This process is seen as an affordable, reliable way for automotive companies to make parts for their cars in mass quantities, according to the same set of precise measurements and standards.

Final Word

It’s clear to see that injection molding has many different uses and applications, and this list is just a small sample of some of the ways in which this process is used. It can help with the creation of almost any kind of plastic or metal part, being used for making daily consumer goods, car parts, medical tools, and so much more. In short, this is one of the most versatile and useful production processes known to man.

Follow Me

Unleashing the Power of the Office Accelerator: Maximizing Productivity and Efficiency in the Workplace with Office 365 Accelerator

Unlocking the Hidden Potential of Your Website: Strategies for Growth

From AI to VR: How Cutting-Edge Tech Is Reshaping Personal Injury Law in Chicago

Trending

Microsoft4 years ago

Microsoft4 years agoMicrosoft Office 2016 Torrent With Product Keys (Free Download)

Torrent4 years ago

Torrent4 years agoLes 15 Meilleurs Sites De Téléchargement Direct De Films 2020

Money4 years ago

Money4 years ago25 Ways To Make Money Online

Torrent4 years ago

Torrent4 years agoFL Studio 12 Crack Télécharger la version complète fissurée 2020

Education3 years ago

Education3 years agoSignificado Dos Emojis Usado no WhatsApp

Technology4 years ago

Technology4 years agoAvantages d’acheter FL Studio 12

Technology4 years ago

Technology4 years agoDESKRIPSI DAN MANFAAT KURSUS PELATIHAN COREL DRAW

Education3 years ago

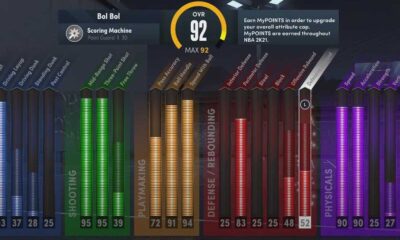

Education3 years agoBest Steph Curry NBA 2K21 Build – How To Make Attribute, Badges and Animation On Steph Curry Build 2K21

You must be logged in to post a comment Login