Education

What is the best portable power pack?

Published

3 years agoon

By

techonpcHydraulics is a fascinating field, and its technology has a rich history. There have been some significant breakthroughs in hydraulic engineering since the establishment of Pascal’s Law in 1647-48 until now.

Since the medieval era, water has been utilized to power machines throughout the world. Though understanding about the different components of hydraulic equipment is a complicated but rewarding process. Hydraulic power packs are a focal point of many pieces of machinery.

Portable gas-powered hydraulic pumps are utilized in a wide range of sectors and may be found in various forms and sizes. While some devices can work with a built-in power source, others demand the degree of power that only these standalone power packs can offer. They also come with a slew of other benefits that might help a variety of enterprises.

You might have come here searching for all the detailed guidelines on the portable hydraulic power pack and portable gas-powered hydraulic pump. Don’t worry since we have got you covered.

Let’s dive deep into the ocean of hydraulic power packs.

What is a hydraulic power pack?

In its most basic form, a hydraulic power pack is a self-contained unit that primarily consists of a motor, a reservoir, and a hydraulic pump. Hydraulic power packs create large quantities of power that may be utilized to operate hydraulic machines using fluid to transport energy from one point to another.

When significant lifting or repetitive directed force is required, portable gas-powered hydraulic pumps are the ideal option, taking their strength from Pascal’s law of physics-defined ratios of area and pressure.

What is the Process of Using a Hydraulic Power Pack?

A portable gas-powered hydraulic pump uses an enclosed fluid to transmit energy from one source to another, resulting in rotational, linear, or force motion. This fluid transfer requires power, which is provided by the power unit/pack.

Hydraulic power units, unlike traditional pumps, transport fluid via multi-stage pressurization networks and frequently include temperature control systems. A hydraulic power unit’s mechanical qualities and specifications determine the kind of tasks it can handle.

Pressure restrictions, power capacity, and reservoir volume are all significant parameters that impact the functioning of a hydraulic power unit. Its physical properties, such as size, power supply, and pumping strength, are also essential factors to consider.

Looking at the fundamental components of a standard model used in industrial hydraulic systems will help you better grasp a hydraulic power unit’s working principles and design aspects.

Best portable gas-powered hydraulic pump – How to select it?

The motor is the power source, or prime mover, for most portable gas-powered hydraulic pumps, and it is often chosen based on its speed, torque level, and power capacity. In the long run, a motor whose size and capabilities complement the hydraulic power unit can reduce wasted energy and increase cost-efficiency.

The parameters for selecting a motor vary depending on the type of power source used. An electric motor, for example, has a much higher initial torque than its operating torque. In contrast, diesel and gasoline-powered engines have a more consistent torque-to-speed curve, delivering a relatively constant torque at both high and low running speeds.

As a result, if the internal combustion engine is not correctly matched with the portable gas-powered hydraulic pump, it may be able to start a loaded pump but not supply enough power to get it up to working speed.

Motor Size

A motor used with a hydraulic power unit should have a power rating at least double that of an electric motor acceptable for the same system. However, the cost of power consumed by an electric motor throughout its operating lifespan generally exceeds the cost of the engine itself, making it critical to select an adequately sized unit that does not waste energy.

Motor size may be determined using the following factors if the pumping pressure and liquid flow are kept constant:

- Amount of Horsepower

- Gallons of water per minute

- Pressure is expressed in psi (pounds per square inch) (psi)

- Pumping efficiency (mechanical)

In certain situations, portable gas-powered hydraulic pumps may need different pressure levels at different phases of the pumping operation. Thus horsepower can be computed as the root mean square (RMS), and a smaller motor may be sufficient for the project.

However, the motor must be able to fulfill the torque requirement for the cycle’s most incredible pressure level.

Once the rms and maximum torque (including starting and operational levels) have been computed, they may be compared to the performance tables of a motor manufacturer to see if the motor is the right size.

The Power of Electric Motors

The torque characteristics of electric motors and internal combustion motors, such as engines, determine their varied power capabilities. A three-phase electric motor turns a rotor to begin its operation sequence. The torque level lowers somewhat as the rotor accelerates, then rises again when the rotation reaches a specific rpm rate.

The momentary decrease in torque is called “pull-up torque,” while the highest amount is referred to as “breakdown torque.” Torque drops sharply as the rotor speed exceeds the breakdown level.

The torque-to-speed curve of an electric motor is essentially the same regardless of power capacity. It is usually driven at maximum load but below the breakdown point to avoid stalling.

Motor Power

Internal combustion motors feature a torque-to-speed curve that is considerably different, with more minor torque variations. Diesel and gasoline engines, in general, must run at more incredible speeds to generate the necessary torque to drive a pump.

An internal combustion engine with a horsepower rating around two and a half times that of an electric motor counterpart is generally required to meet the torque levels needed for a hydraulic power unit.

Manufacturers often suggest that gasoline or diesel motors run at just a fraction of their maximum rated power for the duration of their lives and maintaining torque below maximum can frequently increase fuel economy.

Are you interested in buying a portable gas-powered hydraulic pump for yourself?

If you also want a portable hydraulic pump for yourself, you can get it from the best portable gas-powered hydraulic pump manufacturers.

Follow Me

Unleashing the Power of the Office Accelerator: Maximizing Productivity and Efficiency in the Workplace with Office 365 Accelerator

Unlocking the Hidden Potential of Your Website: Strategies for Growth

From AI to VR: How Cutting-Edge Tech Is Reshaping Personal Injury Law in Chicago

Trending

Microsoft4 years ago

Microsoft4 years agoMicrosoft Office 2016 Torrent With Product Keys (Free Download)

Torrent4 years ago

Torrent4 years agoLes 15 Meilleurs Sites De Téléchargement Direct De Films 2020

Money4 years ago

Money4 years ago25 Ways To Make Money Online

Torrent4 years ago

Torrent4 years agoFL Studio 12 Crack Télécharger la version complète fissurée 2020

Education3 years ago

Education3 years agoSignificado Dos Emojis Usado no WhatsApp

Technology4 years ago

Technology4 years agoAvantages d’acheter FL Studio 12

Technology4 years ago

Technology4 years agoDESKRIPSI DAN MANFAAT KURSUS PELATIHAN COREL DRAW

Education3 years ago

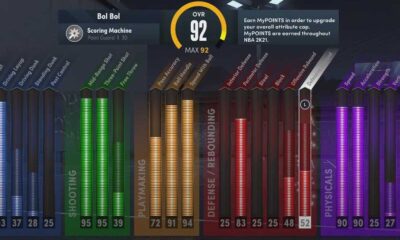

Education3 years agoBest Steph Curry NBA 2K21 Build – How To Make Attribute, Badges and Animation On Steph Curry Build 2K21

You must be logged in to post a comment Login